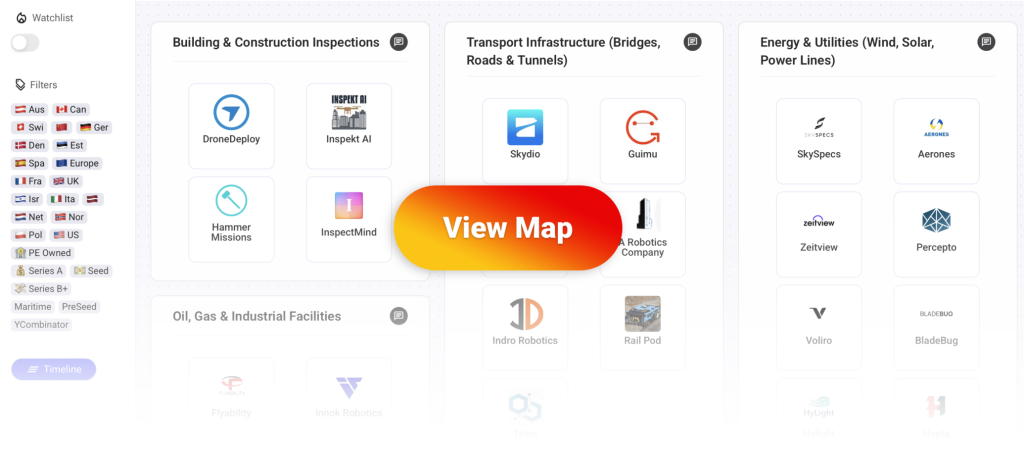

This post is part of a series covering the unbundling of physical inspection. You can view the full interactive map with more than 40 startups here.

The Unbundling of Physical Inspection

In many industries, inspections have traditionally been carried out by human inspectors checking for defects, damage, or maintenance needs. Today, advances in robotics, drones, and AI are unbundling these tasks and automating physical inspections (often still under human supervision). The competitive landscape above is an overview of major categories of physical inspections and companies automating these processes.

Transport Infrastructure (Bridges, Roads & Tunnels)

How inspection is traditionally done:

- Inspectors manually examine bridge decks, tunnel walls for cracks, corrosion, or deformation.

- Lanes are often closed, and scaffolds or rope access are required to reach structural components.

- Measurements and photos are often taken by hand.

- Inspections are time consuming and expose workers to potentially dangerous conditions such as traffic or confined spaces.

How AI and robotics are changing it:

- Drones capture high resolution images and LiDAR scans of bridges and tunnels without the need for closures.

- AI models automatically detect cracks, rust, and surface defects in imagery.

- Specialized climbing and underwater robots can inspect hard to reach or submerged areas like pylons and foundations.

- Digital twins combine sensor data and visual scans to continuously monitor structural health over time and automate reporting/monitoring.

7 Startups Automating Transport Infrastructure (Bridges, Roads & Tunnels) Inspections

🇺🇸 US – 💸 Series B+

What they do:

- They develop autonomous drones that leverage advanced AI and computer vision to fly without continuous human control, serving sectors like inspection, site monitoring, public safety, and utilities.

- Their platforms are used by enterprise and government customers for tasks such as infrastructure inspection, utility asset monitoring, and workshop/hazardous site surveillance.

- The company designs, manufactures and supports its products in the U.S.

- They exited the consumer drone market to focus entirely on industrial, enterprise and defence grade applications.

Company specificities:

- Their autonomy engine enables obstacle avoidance, GPS-denied navigation and mission based autonomous flights.

- These features make their drones suited for complex inspection or surveillance tasks rather than just manual piloting.

- They hold a strong position in high security sectors (including defence and public safety) which demands high reliability.

- Their product roadmap includes enterprise and multi-sensor drones (e.g., thermal, zoom, modular payloads) which allows inspection in low visibility, challenging environments (e.g., utilities, night operations, industrial sites).

🇨🇳

What they do:

- They develop robotic inspection systems for critical transport infrastructure such as airport runways, highways and rail tracks, combining ground penetrating radar and high resolution cameras to capture both surface and subsurface defects.

- Their flagship system autonomously navigates pavements (runways, taxiways, aprons) collecting data on cracks, voids and structural deterioration to support life-cycle maintenance planning.

- They also offer a digital data management platform that processes collected data, creates GIS-tagged maps of defects, and enables users to visualize condition trends and maintenance priorities.

- They serve airports, road/bridge operators and infrastructure asset owners looking for more frequent inspections.

Company specificities:

- Their system achieves high resolution: defect positioning accuracy within ~5 cm and surface resolution as fine as ~0.5 mm, with the capability to detect subsurface problems up to several metres deep.

- It supports large area throughput: for example one model can cover ~7,500 m² per hour on airport pavement.

- The technology is built for full lifecycle management rather than one off inspection.

- They have demonstrated deployments in critical environments (e.g., major airports) and apply multi-sensor fusion (radar + vision + positioning) to move beyond simple visual checks.

🇪🇺 Europe

What they do:

- OMICRON develops an intelligent platform that uses digital inspection, predictive maintenance, and robotics to modernize how roads and bridges are maintained.

- It combines aerial and ground based data collection with AI-driven decision tools to monitor infrastructure condition in real time.

- The project runs pilot programs on major European highways to test how automation can improve safety and reduce traffic disruption.

- Its goal is to make road maintenance more efficient, less costly, and safer for both workers and drivers.

Project specificities:

- Funded by the European Union’s Horizon 2020 program, it brings together research institutes, robotics firms, and infrastructure operators across Europe.

- The project takes a full lifecycle view of infrastructure, linking inspection, diagnosis, and repair in one automated workflow.

- Its robotic platform can carry out maintenance tasks such as sealing cracks or replacing signage without interrupting traffic.

- A strong emphasis is placed on safety, using automation and real-time monitoring to keep workers away from hazardous environments.

🇺🇸 US – 💵 Seed

What they do:

- aRC builds robotic inspection systems that assess the condition of roads, runways, and bridges using advanced imaging and scanning technologies.

- Their robots measure surface and subsurface integrity, detecting issues like cracks, voids, and uneven density across large areas.

- The same systems can support maintenance preparation by cleaning or removing coatings through precise laser ablation.

- Their goal is to make infrastructure inspections faster, more accurate, and less disruptive to traffic and operations.

Company specificities:

- Their robots are designed for continuous operation, allowing inspections to take place without halting traffic or closing lanes.

- The company focuses on measurable outcomes, helping infrastructure operators cut maintenance costs while improving asset longevity.

- They design and manufacture their systems to meet high reliability and safety standards required for critical infrastructure.

- Their combination of surface imaging and non-destructive subsurface analysis provides a more complete picture of road and bridge health.

🇨🇦 Can – 💵 Seed

What they do:

- The Street Smart Robot is a ground based platform designed to inspect bike lanes and nearby roads, identifying dangers such as potholes, debris, and ice.

- It uses cameras, depth sensors, and GPS tagging to detect issues and send location based alerts to municipal maintenance teams.

- The robot operates reliably in harsh winter conditions, using tracked locomotion to navigate snow.

- It currently operates under remote supervision but is being developed for greater autonomy to enable wider city deployment.

Company specificities:

- The SSR combines multiple sensor types, including stereo vision, LiDAR, and infrared imaging, to assess surface and environmental conditions accurately.

- It connects through high speed 5G networks, enabling fast streaming of inspection data to city control centers.

- Its design focuses on the specific challenges of cold climate cities, addressing safety for cyclists and pedestrians during winter.

- The system helps municipalities shift from reactive maintenance to proactive infrastructure management through continuous monitoring.

🇺🇸 US – 💸 Series B+

What they do:

- RailPod provides an automated inspection system for rail infrastructure that collects track geometry, LiDAR, and high-resolution imagery in a single run.

- The platform serves rail operators, maintenance teams, and infrastructure owners who need continuous monitoring and condition assessment.

- A cloud-based portal allows users to review imagery, visualize defects, and compare inspection results over time.

- Their mobile app complements the robotic system by enabling field crews to log defects and synchronize manual observations with automated data.

Company specificities:

- The system captures multiple data types at once, minimizing the time tracks need to be taken out of service.

- It detects and classifies issues such as joint bar wear, ballast degradation, fastener condition, and overhead line defects.

- Data is delivered in a GIS compatible format that enables virtual track walks and remote inspection from collected imagery.

- RailPod’s approach allows more frequent and cost effective inspections, helping operators shift toward preventive maintenance.

🇨🇭 Swi – 🇪🇺 Europe – PreSeed

What they do:

- TALPA develops a robotic inspection system that detects corrosion inside reinforced concrete structures without damaging or drilling into them.

- The technology uses a water-based electrochemical sensing method to measure corrosion probability in steel reinforcement.

- It is designed for infrastructure operators managing tunnels, bridges, retaining walls, and other large concrete assets that are difficult to access.

- The system includes software that interprets sensor data and provides corrosion maps to guide maintenance decisions.

Company specificities:

- Their inspection method works through a thin layer of water, allowing sensors to operate without direct contact and making it suitable for use on drones or robotic arms.

- The company originated from ETH Zurich research and is built on patented technology for localizing corrosion in reinforced concrete.

- The approach enables continuous surface scanning instead of limited sampling, offering higher coverage and earlier fault detection.

- It replaces traditional scaffolding or drilling inspections with a faster, safer, and more data-driven alternative.