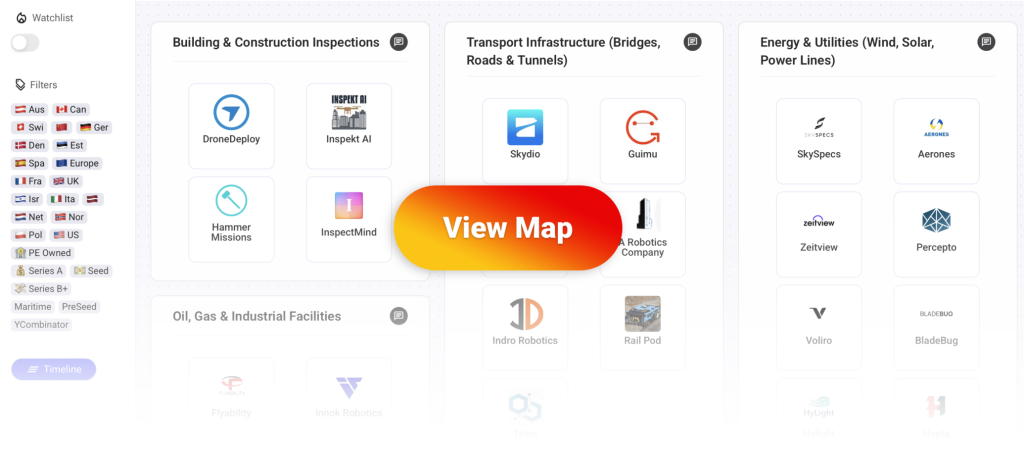

This post is part of a series covering the unbundling of physical inspection. You can view the full interactive map with more than 40 startups here.

The Unbundling of Physical Inspection

In many industries, inspections have traditionally been carried out by human inspectors checking for defects, damage, or maintenance needs. Today, advances in robotics, drones, and AI are unbundling these tasks and automating physical inspections (often still under human supervision). The competitive landscape above is an overview of major categories of physical inspections and companies automating these processes.

Energy & Utilities (Wind, Solar, Power Lines) Inspection

How inspection is traditionally done:

- Technicians climb wind turbines, utility poles, and towers to visually inspect for wear, corrosion, or damage.

- Ground crews manually check solar panels for cracks, dirt buildup, or electrical faults using handheld instruments.

- Helicopters or binoculars are sometimes used to inspect long stretches of power lines.

- Inspections are infrequent, labor intensive, and depend heavily on human observation, making early fault detection difficult.

How AI and robotics are changing it:

- Drones equipped with thermal and optical cameras capture detailed imagery of turbines, panels, and power lines at scale.

- AI models analyze footage to automatically detect blade erosion, hotspot anomalies, or damaged conductors.

- Climbing and crawling robots inspect turbine blades, poles, or insulators up close without human ascent.

- IoT sensors continuously monitor temperature, vibration, and current flow to predict failures before they occur.

10 Startups Automating Energy & Utilities (Wind, Solar, Power Lines) Inspection

🇺🇸 US – 💸 Series B+

What they do:

- SkySpecs provides autonomous drone inspections for wind turbine blades, capturing detailed imagery and structural data to help operators understand asset condition.

- Their platform is used by wind farm owners, OEMs and operations teams who need frequent and consistent inspections to manage maintenance and performance.

- Their software aggregates inspection results, diagnoses blade issues and supports maintenance planning across entire wind portfolios.

- They also inspect related assets such as towers, nacelles and transmission equipment to give operators a broader view of infrastructure health.

Company specificities:

- Their drones fly autonomously with very limited pilot input, allowing a full turbine inspection to be completed quickly and with minimal downtime.

- Their Horizon software suite unifies condition monitoring, analytics and repair planning so operators can manage the full lifecycle of turbine components.

🇪🇺 Europe – 🇱🇻 – 💸 Series B+

What they do:

- Aerones provides robotic services for wind turbines, covering inspection, internal blade assessment, cleaning and leading edge repair.

- They use specialized drones and crawler robots to access turbine blades and towers without the need for rope access crews.

- Their services support wind farm operators and OEMs who need.

- They deliver full maintenance workflows by combining inspection, cleaning and repair in a single service model.

Company specificities:

- Their robotic systems complete inspections and repairs significantly faster than traditional methods, reducing turbine downtime.

- The company has developed patented technology dedicated to wind turbine blade care, giving them capabilities that generalist inspection providers cannot offer.

🇺🇸 US

💸 Series B+

What they do:

- Zeitview provides an inspection software platform that uses drone and visual data to supply detailed condition insights for critical infrastructure such as wind farms, solar arrays, power lines, telecom towers and commercial properties.

- They enable operators and asset managers to view, monitor and assess structural or component health by capturing imagery, generating inventory metadata and tracking issues over time.

- Their platform supports different phases of an asset’s lifecycle: from pre-construction site surveys through ongoing maintenance and final hand off inspections.

- They aim to deliver safer and faster inspections at lower cost by applying artificial intelligence and machine learning to large volumes of visual data.

Company specificities:

- They maintain a global network of pilots and capture service partners, allowing inspections across many geographies without each client having to build their own drone team.

- Their software is designed to integrate with existing inspection photos or new capture, offering flexibility for customers who already have data and want to apply analytics.

- They focus on renewable energy and sustainable infrastructure, positioning their offering where inspection complexity and scale are high and cost savings are significant.

- Their deliverables go beyond fault detection to include inventory tracking, issue severity assessment and actionable maintenance planning insights, helping asset owners move toward proactive management.

🇮🇱 Isr – 💸 Series B+

What they do:

- Percepto provides an autonomous drone in a box system that performs routine inspections and monitoring for industrial sites such as utilities, oil and gas facilities, solar farms, mines and ports.

- Their system captures visual, thermal and analytical data that helps operators monitor equipment, detect anomalies and respond to issues more quickly.

- The platform enables remote supervision of multiple sites, allowing frequent inspections without requiring on site pilots.

- Typical use cases include visual checks, thermal surveys, emissions detection, construction monitoring and security patrols.

Company specificities

- Percepto offers a full stack solution that includes autonomous drones, docking stations, analytics software and cloud data management in a single ecosystem.

- Their AIM platform organizes inspection data, tags anomalies, supports trend analysis and integrates with enterprise workflows.

- Their focus on compliance tasks such as emissions and methane detection positions them well in highly regulated industries.

🇨🇭 Swi – 🇪🇺 Europe – 💰 Series A

What they do:

- Voliro develops an aerial robotic platform that performs non destructive testing and visual inspections on industrial assets such as tanks, chimneys, pipelines and wind turbines.

- Their drone can make controlled contact with surfaces, allowing sensors to measure wall thickness, coating integrity and other structural properties.

- The system helps inspection teams work on high or hard to reach structures without scaffolding or rope access.

- It is designed for asset owners and inspection service providers who need precise and reliable data in complex environments.

Company specificities:

- Their drone uses an omnidirectional design that maintains stable contact on curved or inclined surfaces, enabling accurate ultrasonic and coating measurements.

- It operates in tight or GPS denied spaces, providing navigation and positioning suited for industrial environments.

- The system is purpose built for contact based inspection rather than adapted from consumer drones, giving it higher precision and safety.

- Voliro supports data integration with enterprise systems, helping operators move toward more frequent and proactive inspection cycles.

What they do:

- BladeBUG develops robotic inspection systems for wind turbine blades that can climb and adhere to blade surfaces to perform detailed assessments.

- Their technology is used by wind farm operators and maintenance teams who need to detect structural faults.

- The platform supports inspections of both onshore and offshore wind turbines, enabling safe access to hard-to-reach blades.

- They focus on non destructive testing methods that allow early detection of defects.

Company specificities:

- BladeBUG’s robot can adhere to and traverse vertical curved surfaces of turbine blades.

- The company combines robotics and advanced sensor payloads to deliver subsurface inspection data that visual methods cannot capture.

- They enable increasing inspection frequency and predictive maintenance by turning raw condition data into actionable insights for asset owners.

🇪🇺 Europe – 🇫🇷 Fra – 💵 Seed

What they do:

- HyLight builds autonomous hydrogen powered airships that perform large scale inspections of power lines, pipelines, rail corridors and other linear infrastructure.

- Their airships carry imaging, LiDAR and additional sensors to detect defects, vegetation risks, leaks and other anomalies over very long flight durations.

- They serve utilities and infrastructure operators who need continuous monitoring of extensive networks with lower operational cost and environmental impact.

- The platform turns captured data into insights that help maintenance teams prioritize interventions and reduce outage risks.

Company specificities:

- Their use of hydrogen enables zero emission flights while also providing far longer endurance than conventional drone platforms.

- The airship design allows both stable hovering for close inspection and wide area coverage for corridor monitoring.

- HyLight focuses on fully autonomous operation and integrated analytics so inspections can be run with minimal human involvement.

- Their solution addresses inspection challenges where traditional aircraft or drones are too expensive, too short range or too carbon intensive.

🇪🇪 Est – 🇪🇺 Europe – 💵 Seed

What they do:

- Hepta Insights provides end to end inspection solutions for power grid infrastructure using drones, helicopters or satellite data to capture detailed imagery and sensor information.

- Their platform helps utilities detect issues such as damaged components, corrosion, thermal hotspots and vegetation encroachment along transmission and distribution lines.

- They serve both transmission and distribution operators.

- The system turns raw inspection data into actionable work orders that support reliability, safety and outage prevention.

Company specificities:

- Their platform combines multiple data sources including visual imagery, thermal data, LiDAR and satellite inputs into one analytical workflow for grid operators.

- Machine learning models assign severity levels to detected faults and rank items so maintenance teams can focus on the most critical issues first.

- Hepta offers both software and turnkey inspection services, making their solution accessible even to utilities without internal drone or analytics teams.

🇪🇸 Spa – 🇪🇺 Europe – 💵 Seed

What they do:

- FuVeX develops long range drones that perform automated inspections of critical infrastructure such as power lines, pipelines and other linear networks.

- Their system enables flights beyond the visual line of sight of the pilot, allowing wide area monitoring of infrastructure assets in remote or difficult terrain.

- The company works with energy utilities and other infrastructure operators that require large scale and frequent inspection.

- Their drones capture high resolution imagery and sensor data that replace traditional helicopters for inspection missions.

Company specificities:

- FuVeX has achieved regulatory authorisations for beyond visual line of sight operations over power lines in Europe.

- Their drone models are designed for very long ranges, able to cover tens to hundreds of kilometres in one mission, which exceeds the reach of typical commercial drones.

- They have developed patented technology in aircraft design and imaging resolution that provide high accuracy inspections and enable cost reductions compared to manned aircraft.

- Their business model aims at turning inspections into a continuous service.

🇩🇰 Den – 🇪🇺 Europe

What they do:

- Capra Robotics develops a mobile robot platform that performs autonomous inspections, logistics tasks and urban maintenance for a wide range of environments.

- Their robots operate outdoors and indoors to inspect substations, patrol perimeters, monitor industrial sites and support material flows on factories and logistics yards.

- They provide real time alerts and remote monitoring capabilities.

- The system supports fleet management, data logging and integration with enterprise systems so that inspection and logistics data become actionable.

Company specificities:

- Their robot platform is highly modular so the same base unit can be fitted with inspection, logistics or maintenance tool modules depending on application.

- It uses advanced navigation including GNSS, RTK corrections, odometry and AI vision to enable precise outdoor positioning and operation in complex terrain.

- The company emphasizes one platform for multiple use cases thereby offering scalability and flexibility rather than single purpose machines.

- Their solution targets both inspection and logistics workflows which means clients benefit from both asset monitoring and material handling capabilities.