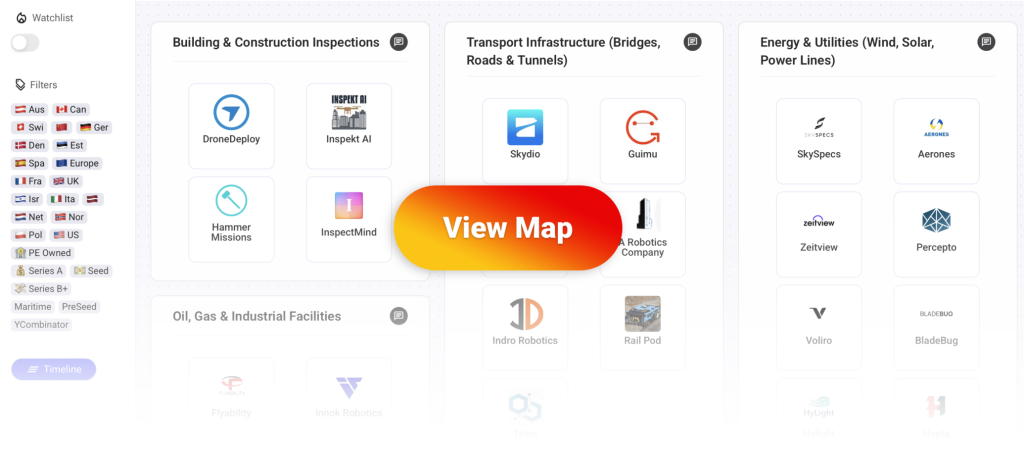

This post is part of a series covering the unbundling of physical inspection. You can view the full interactive map with more than 40 startups here.

The Unbundling of Physical Inspection

In many industries, inspections have traditionally been carried out by human inspectors checking for defects, damage, or maintenance needs. Today, advances in robotics, drones, and AI are unbundling these tasks and automating physical inspections (often still under human supervision). The competitive landscape above is an overview of major categories of physical inspections and companies automating these processes.

Oil, Gas & Industrial Facilities Inspection

How inspection is traditionally done:

- Inspectors manually enter confined spaces like tanks, pressure vessels, and pipelines to perform visual checks or ultrasonic thickness measurements.

- Scaffolding and rope access are used to reach high or complex structures such as refinery columns or flare stacks.

- Shutdowns are often required to allow safe human entry, leading to production downtime and high costs.

- Inspections rely on manual recording and interpretation, which can vary between inspectors.

How AI and robotics are changing it:

- Autonomous or remotely operated robots inspect confined or hazardous areas, eliminating the need for human entry.

- Crawler robots and magnetic climbers carry cameras, ultrasonic probes, and sensors to collect structural data safely.

- AI algorithms analyze visual, thermal, and ultrasonic data to detect corrosion, cracks, and wall-thickness loss automatically.

- Drones and ground robots perform inspections during operations, reducing or eliminating the need for shutdowns.

- Integrated digital systems combine sensor data, 3D mapping, and predictive analytics to plan maintenance and ensure compliance.

11 Startups Automating Oil, Gas & Industrial Facilities Inspection

🇨🇭 Swi – 🇪🇺 Europe – 💸 Series B+

What they do:

- Flyability designs and manufactures drones specially built to inspect indoor and confined spaces such as tanks, boilers, chimneys, tunnels and industrial vessels safely without human entry.

- Their platforms gather imagery, 3D mapping data and sensor readings to help asset owners assess condition, detect defects and plan maintenance.

- They support industries like power generation, oil and gas, chemicals, maritime and large infrastructure where access is difficult and risk is high.

- Their solutions aim to reduce downtime, eliminate the need for scaffolding or human entry and enhance worker safety during inspection operations.

Company specificities:

- Their drones are collision tolerant and designed from the ground up for tight, complex, GPS-denied environments.

- Their flagship model includes interchangeable payloads for visual inspection, ultrasonic thickness measurement and mapping, enabling multiple inspection modes in one platform.

🇩🇪 Ger – 🇪🇺 Europe – 💰 Series A

What they do:

- INSPECTOS is an autonomous mobile robot that follows predefined routes to perform routine inspections such as capturing images and monitoring equipment.

- It is used in industrial sites, plants and large facilities where assets need regular checks without requiring technicians to be physically present.

- The robot helps detect changes, anomalies and damage in areas that are dangerous or difficult for humans to access.

- It operates both indoors and outdoors, ensuring consistent inspection coverage across large or complex environments.

Company specificities:

- INSPECTOS uses cameras, laser scanners and other sensors to collect detailed inspection data and analyse conditions in real time.

- It offers remote data transmission and secure connectivity so inspection results can be reviewed centrally without on site visits.

- The robot is built for tough environments with robust protection and the ability to operate across a wide temperature range.

- Its modular design allows additional sensors or route adjustments, making it adaptable to various industries and asset types.

🇨🇭 Swi – 🇪🇺 Europe – 💰 Series A

What they do:

- Flybotix builds inspection drones designed for confined and hazardous industrial spaces such as tanks, tunnels, vessels and sewer systems.

- Their drones help asset owners in energy, water, chemical and maritime sectors carry out visual checks and detect defects without sending workers into dangerous areas.

- The platform includes the drone hardware, tools for on site data capture and a cloud system for storing and analysing inspection results.

- Their goal is to make confined space inspections faster, safer and more consistent.

Company specificities:

- Their drone uses a dual rotor design with a protective cage, giving it high stability and manoeuvrability in tight and GPS denied environments.

- It offers longer flight time compared to typical confined space drones and supports powerful lighting and optional sensor payloads.

- Their software allows quick validation of captured data on site and offers cloud workflows that turn footage into actionable insights.

🇩🇪 Ger – 🇪🇺 Europe – 💰 Series A

What they do:

- Energy Robotics provides a software platform that allows inspection robots and drones to operate autonomously in industrial facilities such as oil plants, chemical sites and power infrastructure.

- Their system helps asset owners reduce human exposure to hazardous areas while collecting frequent and reliable inspection data.

- The platform processes visual and sensor data to identify anomalies and support maintenance planning.

- It also manages mixed fleets of robots through a single interface so companies can scale automation across multiple sites.

Company specificities:

- Their software works with many types of robots and drones, allowing companies to keep using their preferred hardware without vendor lock in.

- They specialise in enabling inspections in demanding industrial zones where safety certifications and reliability requirements are very high.

- Their analytics include AI capabilities that detect issues such as faulty gauges, missing components or gas leaks.

- The company has extensive field experience with large deployments and many hours of real industrial inspections.

🇨🇭 Swi – 🇪🇺 Europe – 💸 Series B+

What they do:

- ANYbotics develops autonomous legged robots for industrial inspection that can operate in complex and hazardous environments such as chemical plants, oil and gas facilities, mining sites and rail systems.

- Their flagship robot, ANYmal, collects visual, thermal, acoustic and gas data during routine inspection rounds, providing actionable insights to asset owners.

- The platform serves large asset operators who need consistent monitoring, high uptime and reliable data in places where traditional inspections are difficult or dangerous.

- Their solution helps companies reduce operational risk, improve safety and increase efficiency by automating inspection tasks.

Company specificities:

- The robot is designed to navigate harsh industrial terrain including stairs, rough surfaces and GPS-denied zones, giving it mobility that many inspection systems lack.

- ANYbotics offers a full stack inspection solution combining hardware, software and analytics rather than simply selling a robot platform.

- They have developed versions certified for explosive atmospheres so they can be used in dangerous zones where human inspections are restricted.

- The business model supports robots-as-a-service so clients can adopt automation without large capital expenditure up front.

🇺🇸 US – 💸 Series B+

What they do:

- Gecko Robotics develops robots that climb, crawl or move through confined and hazardous spaces to inspect industrial assets such as boilers, tanks, pipelines and power plants.

- Their systems capture high resolution structural data that helps operators understand corrosion, wall thickness, cracks and other failure risks.

- They serve energy producers, manufacturers, utilities and defense organizations that need reliable asset condition data for safety and maintenance planning.

- The company reduces the need for human entry into dangerous environments by automating inspection tasks and data collection.

Company specificities:

- Their Cantilever platform combines robotic inspections with fixed sensors and analytics to give asset owners a consolidated view of equipment health.

- Gecko’s robots can operate on vertical, horizontal and curved surfaces, offering access that many inspection tools cannot provide.

- They gather far more data in a shorter time compared with manual inspections, allowing more frequent and comprehensive assessments.

- Their offering focuses on measurable operational outcomes such as improved uptime, extended asset life and optimized maintenance strategies.

🇪🇺 Europe – 🇬🇧 UK – 💵 Seed

What they do:

- Invert Robotics builds robotic platforms that inspect confined and hazardous industrial spaces such as tanks, vessels, piping and containers.

- Their robots perform non destructive testing so operators can detect cracks, corrosion or surface defects without sending people into risky environments.

- They serve industries like food production, chemicals, pharmaceuticals, aerospace and energy where asset cleanliness and structural integrity are critical.

- Their solutions speed up inspection workflows and allow more frequent condition monitoring, improving uptime and safety.

Company specificities:

- Their crawlers use a patented vacuum adhesion system that lets them move on smooth surfaces including stainless steel, aluminium and plastic in any orientation.

- The robots are built for high precision inspection and can detect defects that would be difficult to identify through manual visual checks.

- The company focuses strongly on eliminating human entry into confined spaces, reducing both risk and downtime.

- Their offering combines robotic hardware, inspection services and data analysis so customers receive a complete inspection solution.

🇪🇺 Europe – 🇳🇱 Net – 💵 Seed

What they do:

- ExRobotics builds rugged autonomous robots designed for extremely harsh and hazardous industrial environments, especially those where explosive gases or dust are present.

- Their robots perform inspection, monitoring and data collection in facilities such as oil and gas plants, chemical sites and hydrogen processing installations.

- The platforms enable asset owners to carry out frequent and consistent condition checks without sending personnel into dangerous zones.

- The company also offers services for robot deployment, mission planning and support, helping operators integrate automation into their operations.

Company specificities:

- Their robots are certified for use in explosive environments (Zone 1 or equivalent) and built to operate in very tough conditions, with wide temperature range capability.

- They focus on combining hardware, software and services in a single package so customers receive a turnkey inspection automation solution.

- Their design supports fully autonomous missions including navigation, obstacle avoidance and remote operation, reducing human intervention on site.

- The company aligns its technology with safety and sustainability goals, helping customers reduce risk exposure and improve operational efficiency in critical infrastructure.

🇪🇺 Europe

What they do:

- Taurob builds ground robots that carry out inspections, routine rounds and data collection in industrial environments such as oil plants, chemical facilities and mining sites.

- Their robots collect visual, thermal, gas and 3D mapping data to help asset owners understand equipment condition without sending workers into hazardous areas.

- They serve operators who need frequent monitoring in locations where explosive atmospheres or harsh terrain make human access risky.

- Their systems help companies move from occasional manual checks to continuous and automated inspection workflows.

Company specificities:

- Taurob robots are certified for use in explosive zones and are designed to handle extreme temperatures, stairs and rough outdoor terrain.

- Their platform can integrate with existing digital twin or asset management systems thanks to open interfaces and flexible software architecture.

- The company focuses on reducing human exposure, lowering inspection costs and simplifying logistics for large industrial sites.

- Taurob has a strong track record with proven deployments and recognition in industrial robotics competitions, reinforcing trust for safety critical use cases.

🇪🇸 Spa – 🇪🇺 Europe – 💵 Seed

What they do:

- Keybotic develops autonomous robot dogs for industrial inspections across sectors such as chemicals, oil and gas, energy and utilities.

- Their robot, Keyper, follows predefined routes or operates under remote supervision to capture visual, thermal and acoustic data during routine rounds.

- It detects issues such as leaks, temperature anomalies and irregular instrument readings, sending alerts to operators in real time.

- The system allows inspections to occur during normal operations, helping companies avoid shutdowns while maintaining safety and reliability.

Company specificities:

- Keyper is designed for fully autonomous navigation including obstacle avoidance, route planning and operation on stairs or uneven terrain.

- The company uses a robotics as a service model so customers can deploy robots without heavy upfront costs.

- The platform integrates multiple sensor types, offering a comprehensive view of facility conditions that goes beyond basic visual checks.

🇪🇺 Europe – 🇫🇷 Fra – 💵 Seed

What they do:

- Multinnov designs drones and robotic systems specifically for inspection in complex and confined environments such as tanks, tunnels, pipes and industrial silos.

- Their products enable operators in energy, infrastructure and municipal sectors to inspect assets that are difficult to access, reducing time consuming scaffolding and human entry.

- They help clients perform visual diagnostics of structures by identifying corrosion, deformations and cracks with high precision.

- Their focus is on making inspections faster, safer and more cost effective by leveraging advanced robotics.

Company specificities:

- Their inspection drones are built in France to meet high quality standards and offer reliability suited for industrial use.

- The solutions are available with short lead times and feature competitive maintenance costs and warranty terms.

- They address safety critical confined space tasks by allowing remote data capture instead of requiring human presence in hazardous environments.

- Their product line includes compact drones and inspection crawlers that work in GPS-denied, dusty or low-lighting conditions, optimizing coverage in challenging settings.