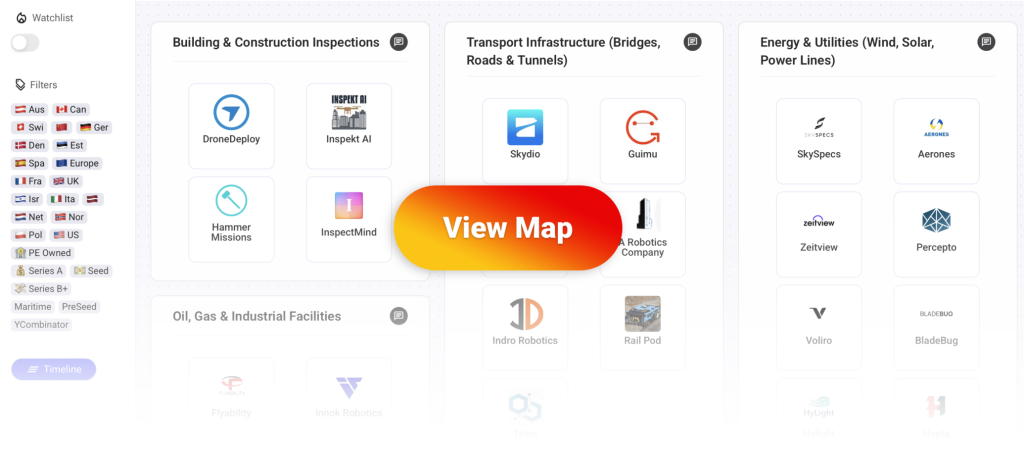

This post is part of a series covering the unbundling of physical inspection. You can view the full interactive map with more than 40 startups here.

The Unbundling of Physical Inspection

In many industries, inspections have traditionally been carried out by human inspectors checking for defects, damage, or maintenance needs. Today, advances in robotics, drones, and AI are unbundling these tasks and automating physical inspections (often still under human supervision). The competitive landscape above is an overview of major categories of physical inspections and companies automating these processes.

Underwater & Maritime Inspections

How inspection is traditionally done:

- Divers perform visual checks of ship hulls, pipelines, and offshore structures using handheld cameras or sensors.

- Manned submersibles are used for deeper or high risk inspections.

- Visibility and environmental conditions make manual inspections slow and dangerous.

- Data collection is limited by dive duration, weather windows, and the high cost of mobilizing teams and vessels.

How AI and robotics are changing it:

- ROVs (remotely operated vehicles) and AUVs (autonomous underwater vehicles) capture high resolution imagery, sonar, and 3D scans without human divers.

- AI systems process visual and sonar data to detect corrosion, cracks, marine growth, or coating degradation automatically.

- Robotic “snake” or crawler systems inspect confined or complex structures such as risers, pipelines, and propeller shafts.

- Continuous monitoring becomes feasible as autonomous vehicles can operate in harsh or deep water conditions more frequently.

- Cloud and edge analytics platforms integrate inspection data into digital twins for maintenance planning and early fault prediction.

8 Startups Automating Underwater & Maritime Inspections

🇪🇺 Europe – 🇵🇱 Pol -💰 Series A

What they do:

- SR Robotics develops underwater and surface robots that perform inspection, maintenance and surveying tasks for aquatic infrastructure.

- Their systems are used to inspect underwater pipelines, ship hulls, hydrotechnical structures and other assets where diver access is risky.

- They support seabed mapping, detection of hazardous objects and environmental data collection in both inland and offshore waters.

- The company offers its robots as a service so operators can access advanced inspection technology without large upfront investment.

Company specificities:

- Their product family includes remotely operated vehicles, autonomous underwater vehicles, autonomous surface vessels and magnetic crawlers for metal structures.

- Their technology incorporates AI and automation to analyse underwater data and support inspection in low visibility or hazardous conditions.

- They also provide robotic hull cleaning solutions that help reduce corrosion, improve vessel efficiency and lower environmental impact.

- The company has a dual use profile, serving both civil and defence related underwater infrastructure needs.

🇦🇹 Aus – 🇪🇺 Europe – 💵 Seed

What they do:

- Subdron develops autonomous underwater robots that inspect ship hulls, port structures and subsea infrastructure without requiring human divers.

- Their systems provide detailed 3D scans and condition data to help operators detect damage, corrosion, biofouling and other underwater issues.

- They serve ports, fleet owners and energy operators that need regular underwater inspections carried out safely and efficiently.

- The company offers its technology as a service so clients can access inspections without owning or maintaining the hardware.

Company specificities:

- Their navigation technology allows the robot to operate very close to underwater surfaces with high positional accuracy.

- The system collects extremely dense measurement data, producing precise 3D models that support early detection of structural issues.

- Their inspections are significantly faster and more cost effective than traditional diver based methods.

- The company also supports sustainability by enabling timely biofouling detection, which helps ship operators reduce drag, fuel use and emissions.

🇪🇺 Europe – 🇳🇴 Nor – 💵 Seed

What they do:

- Eelume builds underwater robots that inspect, monitor and perform light intervention on subsea infrastructure such as pipelines, platforms and mooring systems.

- Their robots can operate autonomously or under remote control, allowing operators to carry out inspections without deploying large surface vessels.

- They serve offshore energy operators in oil and gas, offshore wind and subsea utilities that need frequent and reliable data from deep or hard to reach environments.

- Their systems support subsea resident operation, meaning the robot can stay underwater long term and be deployed on demand.

Company specificities:

- Eelume uses a flexible articulated design that lets the robot navigate narrow, complex or curved underwater spaces where traditional vehicles struggle.

- Their robots are built for long endurance and continuous subsea presence, reducing operational cost and enabling rapid response.

- The platform is modular so payloads can be customized for visual inspection, structural measurements or light maintenance tasks.

- Their approach moves beyond basic imaging by enabling both inspection and intervention, supporting more proactive subsea asset care.

🇪🇺 Europe – 🇳🇴 Nor – 💵 Seed

What they do:

- Blueye Robotics builds professional underwater remotely operated vehicles used to inspect ship hulls, ports, offshore structures, aquaculture farms and pipelines.

- Their ROVs stream live underwater video and allow remote experts to supervise inspections without sending divers into risky conditions.

- They serve maritime operators, energy companies, aquaculture facilities and research groups that need reliable subsea data.

- Their systems aim to reduce inspection cost while enabling more frequent and safer underwater inspections.

Company specificities:

- Their ROVs are designed for professional use with a strong focus on reliability, usability and support.

- The units are self serviceable so customers can deploy and maintain them without requiring specialized technicians.

- They offer various payloads and accessories that allow the same platform to perform diverse underwater inspection tasks.

- The company focuses on enabling easy and frequent access to subsea assets rather than relying on costly and infrequent dive operations.

🇪🇺 Europe – 🇫🇷 Fra – 💸 Series B+

What they do:

- Delair Marine develops underwater drones used to inspect ship hulls, port structures, offshore equipment and other submerged infrastructure.

- Their systems provide high resolution imagery and condition data that help ship owners and operators detect damage, fouling and structural issues.

- They offer both autonomous and tethered vehicles that navigate underwater and capture data in areas that are difficult or unsafe for divers.

- The company also provides software that aggregates inspection data and turns it into clear reports for maintenance planning.

Company specificities:

- Their underwater robots support both inspection and light intervention tasks, enabling work in locations where manual access is limited.

- They focus on fleet wide workflows so large operators can inspect vessels or assets consistently across multiple sites.

- The company promotes safer and more sustainable underwater operations by reducing diver exposure and helping prevent excess fuel consumption linked to hull fouling.

- Delair Marine positions itself as a professional grade provider with systems designed specifically for maritime and underwater industrial applications.

🇨🇦 Can

What they do:

- Deep Trekker builds compact underwater remotely operated vehicles used to inspect ship hulls, pipelines, tanks, ports and other submerged infrastructure.

- Their systems are used in sectors such as energy, aquaculture, defence, public safety and marine research where diver access is difficult or risky.

- The ROVs capture high quality visual, sonar and sensor data to support condition assessments and maintenance planning.

- They provide complete solutions that include the vehicle, tools and support services so organisations can easily adopt underwater inspection capabilities.

Company specificities:

- Their ROVs support modular attachments and sensor payloads and can be configured for different mission depths and environmental conditions.

- The vehicles are designed to be durable, portable and simple to deploy, making them suitable for remote or harsh locations.

- Their support model emphasises long term customer assistance including training, maintenance and spare parts.

- The company helps asset owners conduct more frequent and safer underwater inspections by reducing reliance on divers.

🇪🇺 Europe – 🇮🇹 Ita – 💵 Seed

What they do:

- KeelCrab builds underwater robots that inspect and clean boat hulls for yacht owners, marinas and marine service operators.

- Their robots help detect fouling, algae, corrosion and minor hull damage without lifting the vessel out of the water.

- They support routine hull maintenance and allow service providers to offer regular underwater cleaning as part of their operations.

Company specificities:

- The robot uses suction to adhere to the hull and moves with tracked brushes while streaming video to the operator for real time inspection.

- The system can be remotely controlled from the surface and also supports a mode where a diver can guide the platform while it stays attached.

- Their products are designed and manufactured in Italy with a focus on reliability and ease of use for everyday marine environments.

- The robot has a compact look with a rounded plastic shell, tank style tracks and a low profile that allows it to glide smoothly along curved hull surfaces.

🇳🇴 Nor

💵 Seed

Maritime

What they do:

- Kongsberg Ferrotech develops robotic systems for inspection, maintenance and repair of underwater installations.

- They deploy remotely operated robots capable of handling tasks on subsea infrastructure in sectors such as offshore energy, maritime and wind-power.

- They employ advanced technologies including underwater 3D metal printing and robotic habitats that allow repairs to be done in situ rather than via full retrieval to surface facilities.

- Their services aim to reduce costs, increase operational efficiency and minimise reliance on divers or major downtimes for asset repair.

- The robot has a large yellow rectangular body with mounting frames and a hatch-like front, built to be deployed from a crane over the side of a vessel and lowered into the sea.

How they differentiate:

- Their robots and habitats are designed specifically for subsea operations under difficult conditions, enabling higher repair quality and less human risk than conventional diver based methods.

- They integrate repair, inspection and maintenance into a single robotic workflow. It meanis assets can be maintained without full removal or replacement, which is uncommon in the industry.

- Their use of in-situ additive manufacturing (metal-to-metal 3D printing underwater) enables repairs that would otherwise require dry-dock or surface interventions.