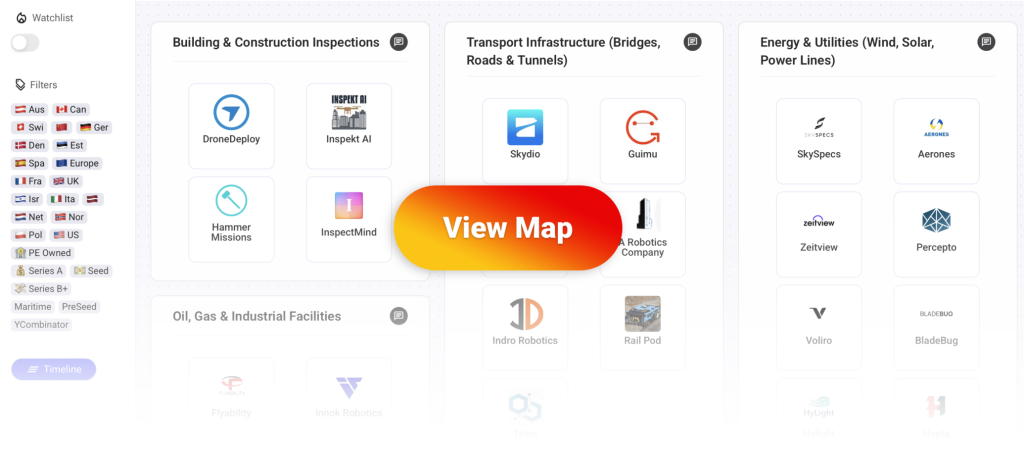

This post is part of a series covering the unbundling of physical inspection. You can view the full interactive map with more than 40 startups here.

The Unbundling of Physical Inspection

In many industries, inspections have traditionally been carried out by human inspectors checking for defects, damage, or maintenance needs. Today, advances in robotics, drones, and AI are unbundling these tasks and automating physical inspections (often still under human supervision). The competitive landscape above is an overview of major categories of physical inspections and companies automating these processes.

Water & Sewer Pipe Inspection

How inspection is traditionally done:

- Crews deploy CCTV cameras attached to cables or small wheeled crawlers to visually inspect pipes for cracks or blockages.

- In some cases, workers physically enter large sewer systems to assess structural conditions and perform maintenance.

- Leak detection often relies on indirect signs such as surface flooding, pressure loss, or manual acoustic listening.

- Excavation is sometimes required to access damaged sections, making the process slow and disruptive.

How AI and robotics are changing it:

- Autonomous pipe crawling robots equipped with cameras, sonar, or LiDAR navigate through networks without tethers.

- AI models analyze footage in real time to detect cracks, joint failures, sediment buildup, or leaks automatically.

- Smart sensors embedded in pipelines continuously monitor flow, vibration, and pressure changes to detect early anomalies.

- Robotic systems can perform both inspection and minor repairs, reducing the need for excavation or human entry.

- Centralized data platforms map underground networks and track degradation over time for predictive maintenance planning.

4 Startups Automating Water & Sewer Pipe Inspection

🇺🇸 US – 🏦 PE Owned

What they do:

- Their SOLO robot inspects small diameter sewer and water pipes. It moves autonomously inside the pipe so crews do not need to enter confined spaces or rely on heavy vehicles.

- The platform produces high quality panoramic imagery. It captures a complete view of the pipe interior thanks to front and rear cameras working together.

- The system delivers consistent inspection quality because the robot operates on its own once released. Operator skill has less impact on the final result.

- The value comes from faster deployment, easier access to difficult manholes and higher daily inspection throughput for municipal utilities and engineering firms.

Company specificities:

- The SOLO robot moves by itself inside the pipe. It attempts to bypass obstacles on its own and returns if it cannot continue.

- The design is compact and easy to carry. Crews can deploy it directly from the manhole which helps in areas where large vehicles cannot reach.

- The company focuses on small diameter pipes which lets them optimise for speed and portability in this specific segment.

- The product has been used for many years which gives the company strong field experience and a proven track record in municipal pipeline inspection.

🇩🇪 Ger – 🇪🇺 Europe

What they do:

- The company provides inspection systems for sewer and water pipes. Their products include robotic crawlers, push cameras and fully equipped inspection vehicles.

- Their solutions serve municipal utilities, industrial facilities and inspection service providers who need to assess pipeline conditions with precision.

- The equipment combines cameras and sensors with software that captures data, analyses defects and produces structured inspection reports.

- The value comes from faster inspections, clearer visualization of defects, safer operations in confined spaces and better decision making for maintenance planning.

Company specificities:

- Their systems are designed to be modular. Users can adapt the same core platform to different pipe sizes and missions by changing components.

- The company covers a very wide pipe diameter range with one product family. This makes them suitable for both small laterals and large mainline sewers.

- They have decades of experience in the sector which gives them strong credibility with utilities and professional inspectors.

- Their crawlers integrate advanced measurement functions such as inclination and deformation analysis which provide deeper diagnostic insights than basic video inspection.

🇪🇺 Europe – 🇫🇷 Fra – 💵 Seed

What they do:

- The company develops an autonomous robot that navigates inside drinking water pipes to assess their condition in detail. It moves through the network without requiring service interruption.

- Their solution is designed for water utilities that need precise information about buried assets to plan maintenance and reduce losses.

- The robot measures wall thickness, corrosion, structural defects, flow irregularities and alignment issues to provide a clear view of pipe health.

- The main value comes from reducing leaks, avoiding unnecessary excavation and helping utilities prioritise which pipes should be repaired or replaced.

Company specificities:

- Their Pathfinder robot can travel through complex pipe networks with bends and branches while keeping the water system in service.

- They focus on drinking water infrastructure which is rarely inspected internally. This gives them a strong position in a very difficult and underserved segment.

- The solution combines robotics, advanced sensing and precise geolocation which allows utilities to understand both the defect and its exact position underground.

- The company often provides inspection missions as a service which lowers adoption barriers for utilities that do not want to purchase and maintain the hardware themselves.

What they do:

- The company provides inspection equipment for sewer and stormwater networks. Their portfolio includes robotic crawlers, push cameras, manhole cameras and complete inspection vehicles.

- Their products are used by municipalities, utilities and inspection contractors that need to assess underground pipe conditions and document defects.

- Their hardware works together with software workflows that organise video, notes and defect data so teams can turn inspections into actionable maintenance decisions.

- The value comes from faster inspections, clearer documentation, safer operations and better planning for pipe repair or replacement.

Company specificities:

- Their equipment is known for being rugged and reliable which is important for work in harsh sewer environments. They also support customers with a broad service and training network.

- They cover many inspection scenarios from large sewer mains to small laterals and manholes which allows customers to standardise on one vendor.

- They created a structured inspection approach called the Phased Assessment Strategy for Sewers. It helps utilities prioritise their attention by identifying which lines can be inspected quickly and which need deeper review.

- They place strong emphasis on customer education with training programs and practical resources that help teams use the technology effectively.