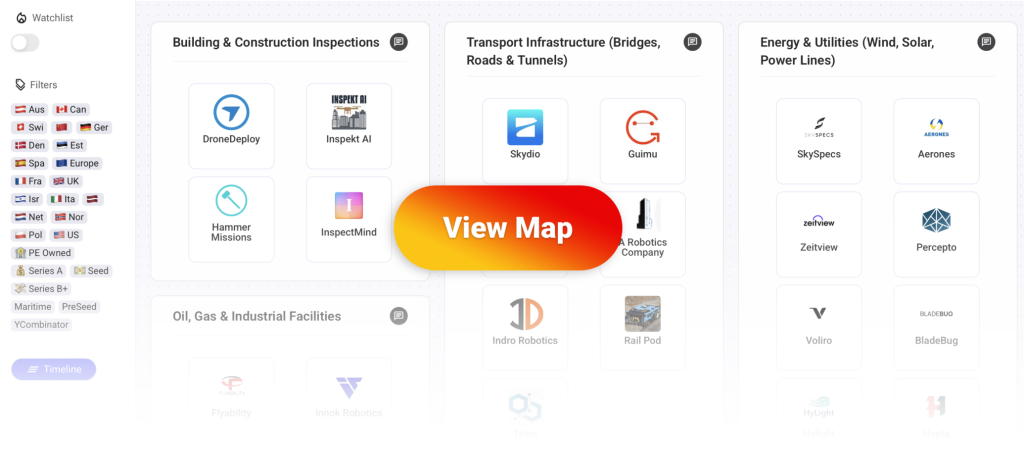

This post is part of a series covering the unbundling of physical inspection. You can view the full interactive map with more than 40 startups here.

The Unbundling of Physical Inspection

In many industries, inspections have traditionally been carried out by human inspectors checking for defects, damage, or maintenance needs. Today, advances in robotics, drones, and AI are unbundling these tasks and automating physical inspections (often still under human supervision). The competitive landscape above is an overview of major categories of physical inspections and companies automating these processes.

Product Quality Inspection

How product inspection is traditionally done:

- Human inspectors visually examine products on production lines to identify visible defects, irregularities, or assembly errors.

- Random sampling is often used instead of full line inspection, increasing the risk of undetected faults.

- Specialized tools such as microscopes or gauges are used for dimensional or surface checks, requiring manual handling.

- Inspection quality depends on human experience and attention, which can vary over inspectors.

How AI and robotics are changing it:

- Computer vision systems monitor production lines in real time, detecting defects or deviations automatically at high speed.

- AI models analyze images, acoustic signals, or spectral data to identify surface and subsurface flaws invisible to the human eye.

- Terahertz, X-ray, and hyperspectral imaging enable non destructive inspection of complex materials and components.

- Automated inspection robots can manipulate parts, measure tolerances, and perform consistent checks without fatigue.

- Integrated analytics platforms connect inspection data to process control systems, enabling predictive quality management and reducing waste.

7 Startups Automating Product Quality Inspection

🇩🇪 Ger – 🇪🇺 Europe – 💵 Seed

What they do:

- They enable visual quality inspection of manufactured parts. Their system is used for items made of metal, plastic or textile and also for components in sectors such as automotive, electronics and pharmaceuticals.

- Their platform uses deep learning to detect defects with high precision. It identifies even subtle irregularities that a human or a classic rule based vision system might miss.

- Their software connects to existing cameras on production lines which helps manufacturers upgrade inspection without replacing hardware.

- The value comes from fewer defective products, more consistent decisions, lower false alarms and faster deployment of inspection models for new product variants.

Company specificities:

- Their models can be trained with very small data sets which lowers the barrier for factories that cannot collect thousands of labelled images.

- They offer a no code interface so production engineers can create and deploy inspection models without specialised AI skills.

- They place strong focus on reducing pseudo defects which helps avoid costly stops in the production flow.

- They are based in Europe and position themselves as a highly flexible inspection platform that adapts to many different materials and sectors.

🇪🇺 Europe – 🇳🇱 Net – 💵 Seed

What they do:

- They enable quality inspection of metal parts by analysing how each part responds to sound and vibration. Their system works well for castings, machined components and other pieces where internal defects matter.

- Their technology excites the part with a controlled impact and listens to the acoustic signature. An AI model then identifies patterns linked to cracks, voids or structural inconsistencies.

- The solution supports full inline inspection which replaces manual sampling and gives manufacturers real time visibility on defects.

- The main value comes from catching hidden flaws early, reducing scrap, lowering warranty risks and avoiding human subjectivity in inspection.

Company specificities:

- They use acoustic resonance as the primary sensing method which offers an alternative to visual inspection, X ray or ultrasound.

- They design their system for integration directly into the production flow so operators do not need to run separate offline checks.

- Their approach is well suited for safety critical sectors where the internal structure of each part must be verified with high confidence.

- They are a young company focusing on rapid scale up in European manufacturing, combining hardware and AI into a single inspection package.

🇪🇺 Europe – 🇫🇷 Fra – 💵 Seed

What they do:

- They enable inline quality inspection of high volume manufactured goods such as hygiene products, textiles and coated materials through terahertz imaging with AI.

- Their system is installed on the production line and performs non destructive checks of internal structure including thickness, material distribution and hidden defects.

- Their solution targets manufacturers that want to move from sampling to complete inspection in order to reduce waste and improve process stability.

- The main value comes from better yield, lower material usage, early detection of anomalies and stronger quality consistency for brands operating at scale.

Company specificities:

- They use terahertz on silicon sensing which makes it possible to see inside materials at production speed, something classic vision systems cannot do.

- They deliver a full stack system that includes hardware, sensors, software and analytics, which simplifies deployment for manufacturers.

- They first focused on the hygiene sector where production volumes are extremely high which helped them gather strong data sets and validate reliability.

- They offer subscription models that combine equipment and analytics which lowers upfront costs for factories adopting the technology.

🇪🇺 Europe – 🇳🇱 Net – 💵 Seed

What they do:

- They enable quality inspection of quantum chips and quantum hardware. Their system identifies structural defects, impurities and anomalies that affect qubit performance.

- Their technology uses advanced scanning probes that measure thermal, electrical and magnetic behaviour at extremely small scales and at cryogenic temperatures.

- Their customers are quantum chip manufacturers and semiconductor research teams that need diagnostic capabilities beyond classic optical or electronic metrology.

- The value comes from improving yield, revealing the precise root causes of chip failure, shortening development cycles and supporting the transition from research scale to production scale quantum hardware.

Company specificities:

- They combine cryogenic scanning microscopy with custom quantum sensors which lets them measure chips in conditions close to their real operating environment.

- They focus exclusively on quantum hardware which places them in a narrow but rapidly growing segment where few inspection tools exist.

- They address a fundamental bottleneck in quantum chip manufacturing by diagnosing why devices underperform rather than detecting only visible surface defects.

- They are an early stage company growing quickly through prototype development and collaboration with quantum manufacturers.

🇪🇸 Spa – 🇪🇺 Europe – 💵 Seed

What they do:

- They enable quality inspection of food products and packaged goods using advanced X ray sensing. Their technology helps detect contaminants in items such as seafood, poultry, nuts and other processed products.

- Their system uses photon counting X ray detectors that analyse the energy signature of each photon. This makes it possible to separate materials with far greater precision than classic grayscale X ray.

- Their customers are food producers and machine integrators that need higher accuracy, fewer false positives and better detection of low density contaminants such as plastics.

- The main value comes from improved product safety, lower waste caused by false alarms, and clearer identification of hidden defects or foreign materials.

Company specificities:

- They use spectral photon counting technology which gives a richer signal than conventional X ray and allows detailed material differentiation.

- Their detectors are designed for inline industrial use which means they can operate at high speed on production lines.

- They come from deep science research and bring strong expertise in sensor physics which is rare in the food inspection space.

- They specialise in material separation and contaminant detection rather than simple surface imaging which gives them a clear niche in food safety inspection.

💰 Series A

What they do:

- They enable quality inspection in semiconductor manufacturing by analysing wafer and chip images along with equipment signals. Their system identifies defects, irregular patterns and early process deviations.

- Their platform automates defect classification and supports decisions such as pass, hold or scrap which helps reduce manual review by engineers.

- Their customers include foundries and advanced chip manufacturers that need to maintain high yield while managing very complex fabrication steps.

- The value comes from fewer defective parts going through, faster cycle times, higher yield and reduced human workload for inspection teams.

Company specificities:

- They offer a no code interface so process and yield engineers can build and adjust inspection models without relying on data scientists.

- Their software connects to a variety of optical inspection tools which makes it compatible with many fabs and avoids heavy hardware changes.

- They provide predictive insights by analysing patterns that indicate where defects are likely to occur which shifts inspection toward proactive control.

- They have proved their impact through measurable gains in accuracy and throughput and have attracted funding from semiconductor focused investors.

🇨🇭 Swi – 💸 Series B+

What they do:

- Delvitech develops AI driven solutions for 3D automated optical inspection (AOI) and solder paste inspection (SPI) of assembled printed circuit boards (PCBs) in electronics manufacturing.

- Their platform uses proprietary neural networks that learn and adapt alongside production environments, aiming to reduce false defect calls and improve overall production quality.

- They combine custom designed hardware (such as patented optical heads) with software to enable high precision inspection across varying board types, component heights and materials.

How they differentiate:

- The company delivers an AI native inspection solution rather than a traditional rule based system.

- They manufacture both hardware and software in-house (with development and production in Switzerland) which gives tighter integration, higher precision and a strong engineering pedigree.

- Their platform is built to scale across different production phases (from SPI to AOI) and varied board sizes/heights, enabling a unified inspection solution rather than multiple separate machines.