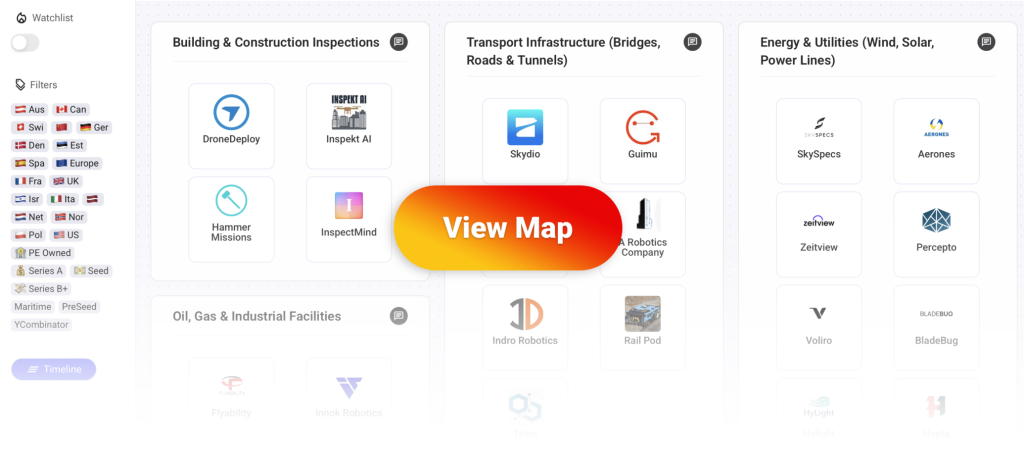

This post is part of a series covering the unbundling of physical inspection. You can view the full interactive map with more than 40 startups here.

The Unbundling of Physical Inspection

In many industries, inspections have traditionally been carried out by human inspectors checking for defects, damage, or maintenance needs. Today, advances in robotics, drones, and AI are unbundling these tasks and automating physical inspections (often still under human supervision). The competitive landscape above is an overview of major categories of physical inspections and companies automating these processes.

Space Inspections

How inspection is traditionally done:

- Pre-launch inspection relies on ground crews visually and mechanically checking satellite components for assembly accuracy and contamination.

- Critical subsystems such as solar panels, sensors, and thrusters are tested under simulated vacuum and vibration conditions.

- Once in orbit, inspection capability is extremely limited and depends on telemetry data or indirect performance indicators.

- Physical damage from debris or micrometeoroids often goes unnoticed until a malfunction occurs.

How AI and robotics are changing it:

- AI systems analyze telemetry, imagery, and sensor data to detect anomalies or early signs of component degradation in orbit.

- Inspection satellites and robotic servicing spacecraft can visually inspect, refuel, or even repair other satellites without human intervention.

- In manufacturing, automated optical and X-ray inspection ensures higher reliability of satellite components before launch.

- Real time data across fleets of satellites allows predictive maintenance and early anomaly resolution, extending mission lifespans.

3 Startups Automating Space Inspection

🇪🇺 Europe – 🇫🇷 Fra – 💸 Series B+

What they do:

- They enable inspection of satellites in orbit. Their spacecraft approaches existing satellites and captures detailed visual and sensor data about their condition.

- Their service is aimed at satellite operators who need to understand structural health, pointing issues or gradual degradation of their assets in geostationary orbit.

- Their system supports tasks such as anomaly detection, orbit assessment and overall asset evaluation so operators can plan maintenance or life extension.

- The value comes from extending satellite lifetime, reducing the need for costly replacements and lowering operational risks through better situational awareness.

Company specificities:

- They use autonomous vision based navigation that lets their servicing spacecraft approach and inspect targets with minimal human intervention.

- They operate directly in orbit which places them in a very different environment from typical industrial inspection companies.

- They combine inspection with on orbit servicing which allows them to both diagnose issues and support corrective actions.

- They focus on high value assets in geostationary orbit which gives them a niche in long term satellite management.

What they do:

- Their product enables in orbit inspection and servicing of satellites. It supports tasks such as visual assessment, health checks, relocation and controlled de orbiting.

- The company provides a modular rendezvous and docking unit that can be integrated into servicing spacecraft so they can approach and attach to existing satellites.

- Their solution is aimed at operators and space agencies that need to extend satellite life, diagnose anomalies in orbit or manage obsolete assets.

- The main value comes from preventing failures, reducing replacement costs, improving orbital safety and enabling active management of satellites already in space.

Company specificities:

- Their docking technology draws on a long heritage of successful space rendezvous missions and has been adapted for autonomous operations.

- The system can attach to satellites that were not originally designed for docking which greatly expands the addressable market.

- They support multiple mission types from inspection to relocation and end of life disposal which positions them as a full service platform rather than a single use tool.

- The company is early stage but advancing quickly with plans for upcoming servicing missions.

🇺🇸 US

What they do:

- Their Otter vehicle enables in orbit inspection and servicing of satellites. It can approach, observe, reposition and safely dispose of client satellites.

- The company serves satellite operators and space agencies that need autonomous rendezvous, proximity operations and docking in low Earth orbit and geostationary orbit.

- The system allows detailed health checks of satellites, supports life extension missions and can relocate or de orbit satellites to manage congestion and reduce risk.

- The main value comes from preventing failures, extending the operational lifetime of hardware already in space, and improving overall orbital safety.

Company specificities:

- The Otter vehicle is designed to be smaller and more affordable than traditional servicing spacecraft which opens the market to more operators.

- Their demonstration missions aim to prove docking with unprepared satellites, a milestone that would validate autonomous servicing at scale.

- Their technology focuses heavily on autonomous rendezvous and docking which is a core capability for any full inspection and servicing mission.

- The company collaborates with major space and defence organisations which strengthens credibility for high value orbital operations.